Etisalat Free Browsing and Downloading Unlimited With Simple Server (PC, Android & Symbian USERS) 2015

No much waste of time, etisalat is crazily rocking on

simple server… I know etisalat tweak doesn’t last but this one has been

rocking since yesterday. Atleast with this, you can download whatever

you want or can think before it will be hijacked by uncoded eti staffs.

But might be very slow in surfing; but best in downloading. Just edit

your simple server to what is below.

How To Setup Simple server For PC Users

L H O S T = ' 1 2 7 . 0 . 0 . 1 '

I M E T H O D = 1

I S P L I T = 0

R H T T P = 0

T I M E O U T = 6 0

P H O S T = ' 1 9 4 . 1 7 0 . 1 8 7 . 9 '

R Q U E R Y = ' '

R P A T H = 0

P T Y P E = 0

K E E P = ' '

B Q U E R Y = ' '

MQ U E R Y = ' '

R H T T P S = 1

P P O R T = 8 0

L P O R T = 8 0 8 0

V A L H D R 1 = ' '

V A L H D R 2 = ' '

V A L H D R 3 = ' '

I Q U E R Y = ' www . e t i s a l a t . c om . n g '

A DMO D E = 0

C Q U E R Y = ' '

C U S H D R 2 = ' '

C U S H D R 3 = ' '

C U S H D R 1 = ' '

I L I N E = 0

F Q U E R Y = ' '

S B U F F = 1 0 2 4

R P O R T = 0

How To setup Simple server For Android & Symbian phone Users

Access Point :- Default

Local Host :- 127.0.0.1

Local Port :- 8080

HTTP Query :-

Front Query : Non

Middle Query : None

Back Query : None

Reverse Query : None

Inject Query : www.etisalat.com.ng

Inject Method : HEAD

Inject Newline : \r\n

Inject Splitline : Default

HTTP Header :-

Custom Header 1 : Host

Header Value 1 : music.vodafone.com.tr Custom Header 2 : None

Header Value 2 : None

Custom Header 3 : None

Header Value 3 : None

Custom Header 4 : None

Header Value 4 : None

Proxy Host :- ' 194.170.187.9 '

Proxy Port : - 80

Then the Set IP and port for PC ,andriod & symbian to :

Ip:127.0.0.1

port: 8080

Mind you, this is not a bb plan, it doesn’t require any airtime or mb.. just Connect, surf and keep downloading until you are tired of downloading.

I M E T H O D = 1

I S P L I T = 0

R H T T P = 0

T I M E O U T = 6 0

P H O S T = ' 1 9 4 . 1 7 0 . 1 8 7 . 9 '

R Q U E R Y = ' '

R P A T H = 0

P T Y P E = 0

K E E P = ' '

B Q U E R Y = ' '

MQ U E R Y = ' '

R H T T P S = 1

P P O R T = 8 0

L P O R T = 8 0 8 0

V A L H D R 1 = ' '

V A L H D R 2 = ' '

V A L H D R 3 = ' '

I Q U E R Y = ' www . e t i s a l a t . c om . n g '

A DMO D E = 0

C Q U E R Y = ' '

C U S H D R 2 = ' '

C U S H D R 3 = ' '

C U S H D R 1 = ' '

I L I N E = 0

F Q U E R Y = ' '

S B U F F = 1 0 2 4

R P O R T = 0

How To setup Simple server For Android & Symbian phone Users

Access Point :- Default

Local Host :- 127.0.0.1

Local Port :- 8080

HTTP Query :-

Front Query : Non

Middle Query : None

Back Query : None

Reverse Query : None

Inject Query : www.etisalat.com.ng

Inject Method : HEAD

Inject Newline : \r\n

Inject Splitline : Default

HTTP Header :-

Custom Header 1 : Host

Header Value 1 : music.vodafone.com.tr Custom Header 2 : None

Header Value 2 : None

Custom Header 3 : None

Header Value 3 : None

Custom Header 4 : None

Header Value 4 : None

Proxy Host :- ' 194.170.187.9 '

Proxy Port : - 80

Then the Set IP and port for PC ,andriod & symbian to :

Ip:127.0.0.1

port: 8080

Mind you, this is not a bb plan, it doesn’t require any airtime or mb.. just Connect, surf and keep downloading until you are tired of downloading.

DOWNLOAD ETISALAT SIMPLE SERVER HERE FOR PC

Download Simple Server For Symbian Users

Android user Download Simple Server here

Download Simple Server For Symbian Users

Android user Download Simple Server here

You can also comment and share to your friends,

Is work perfectly and like jet speed incase if you have a problem or confuse during configure it on your PC.

You can contact me or find me via +2348094994773 ...

Enjoy the downloading speed....

Is work perfectly and like jet speed incase if you have a problem or confuse during configure it on your PC.

You can contact me or find me via +2348094994773 ...

Enjoy the downloading speed....

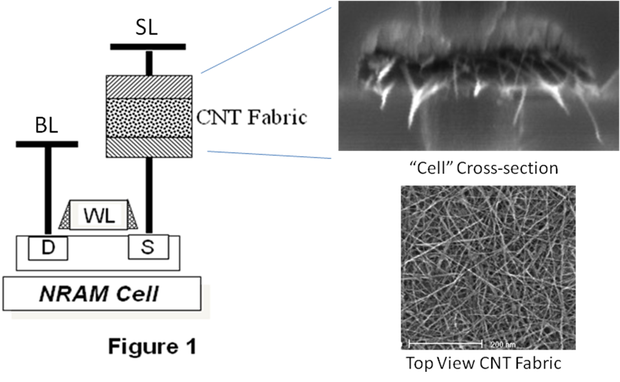

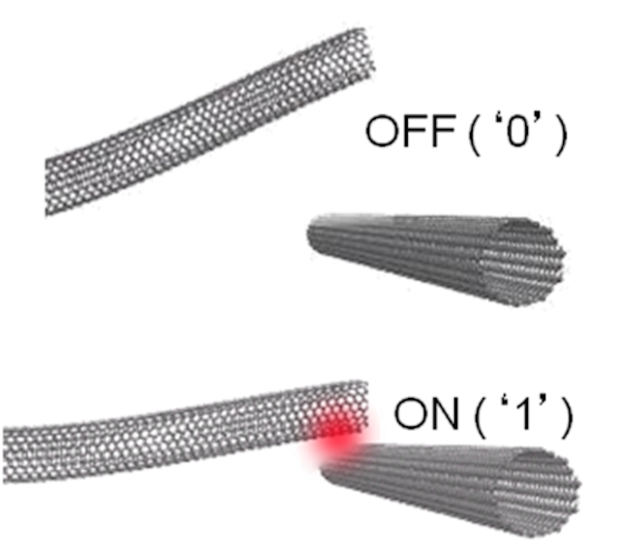

Nantero

Nantero

Nantero

Nantero